Electric Motor Bearing Grease Selection

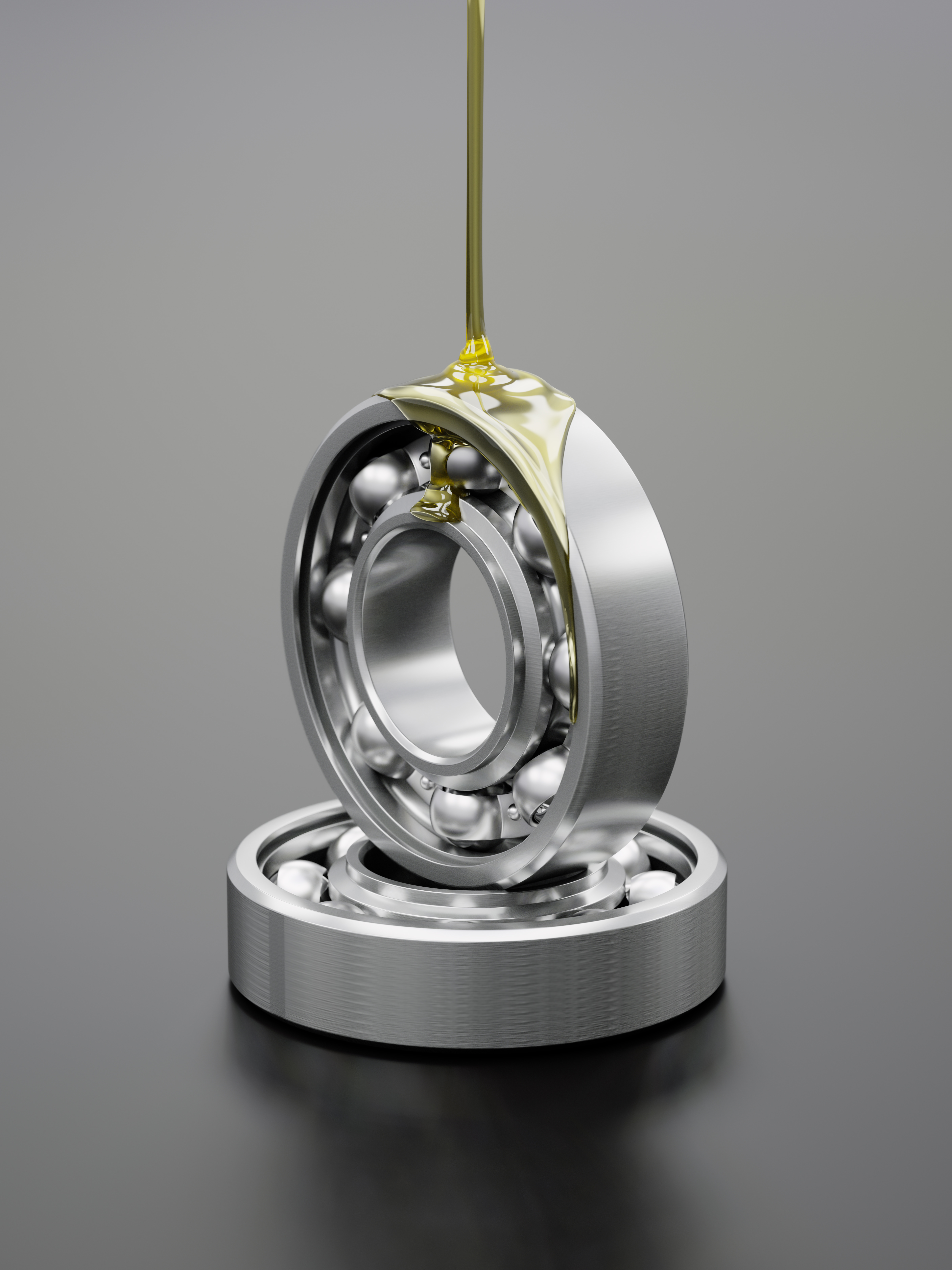

Combined with safety issues proper lubrication can maintain the electric motor reliability.

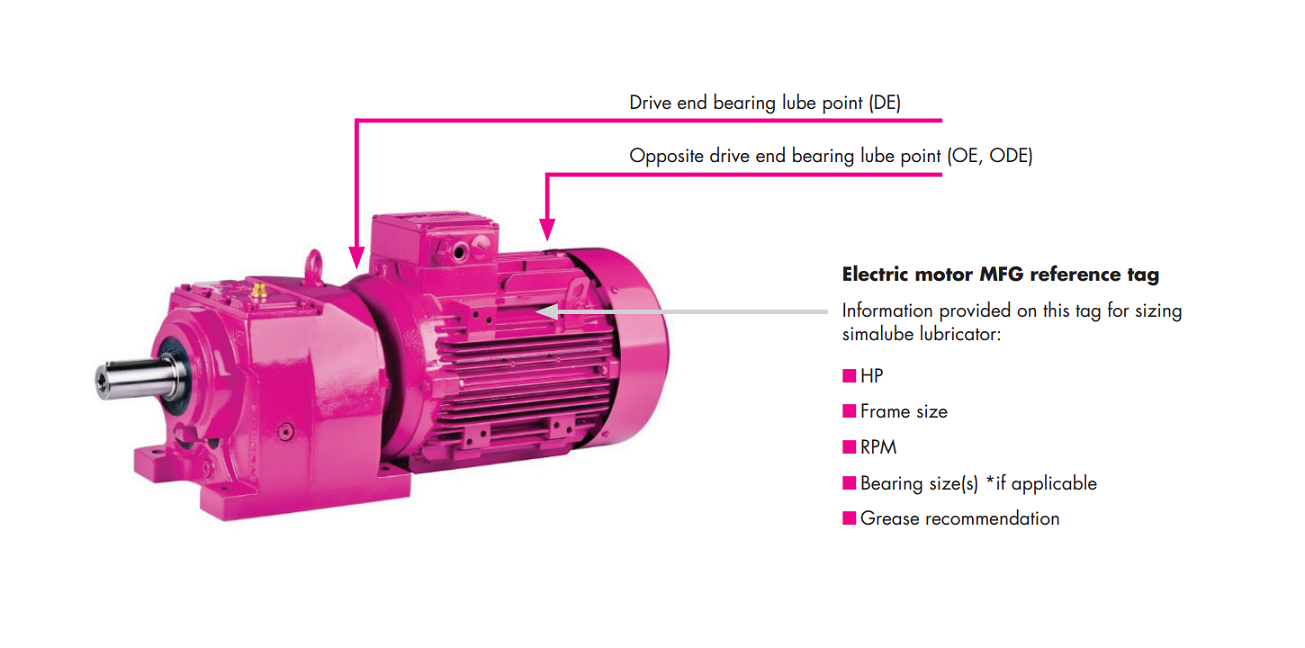

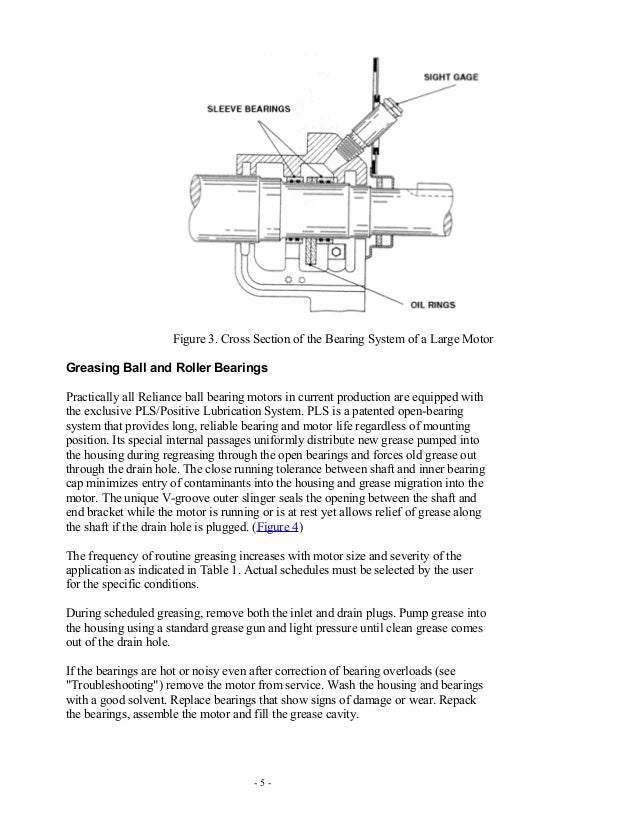

Electric motor bearing grease selection. But choosing the right bearings alone isn t enough. While most would not use an ep 220 gear oil for an oil lubricated electric motor bearing many people will use a grease containing that same oil for an identical grease lubricated bearing. With the motor running pump fresh grease into the bearing while observing the old grease that is being forced out of the grease drain. 1 rotational speed rotational speed r min x 0 5 d d mm.

Nlgi 3 is about the consistency of vegetable shortening. Nlgi 2 is about the consistency of peanut butter. This will help to insure maximum. This too is highly influenced by bearing selection.

The result is reduced risk of excess grease entering the electric motor stator due to couetti flow and reduced viscosity due to heat. Choosing the right electric motor grease important grease characteristics for electric motor bearings the following criteria may be used as typical indicators of a good electric motor grease. Another crucial factor for electric motors is energy efficiency. When the purged grease looks fresh stop pumping.

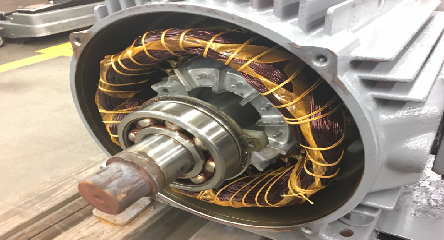

Because the majority of grease lubricated applications are element bearings one should consider viscosity selection for those applications. These include incorrect lubricant selection contamination loss of lubricant and overgreasing this article discusses several effective strategies to minimize the likelihood of these failure modes. Rolling element bearings used in electric motors are at risk for various modes of failure if an incorrect maintenance or lubrication strategy is implemented. Mineral oil based grease derived from petroleum is more economical than synthetic oil.

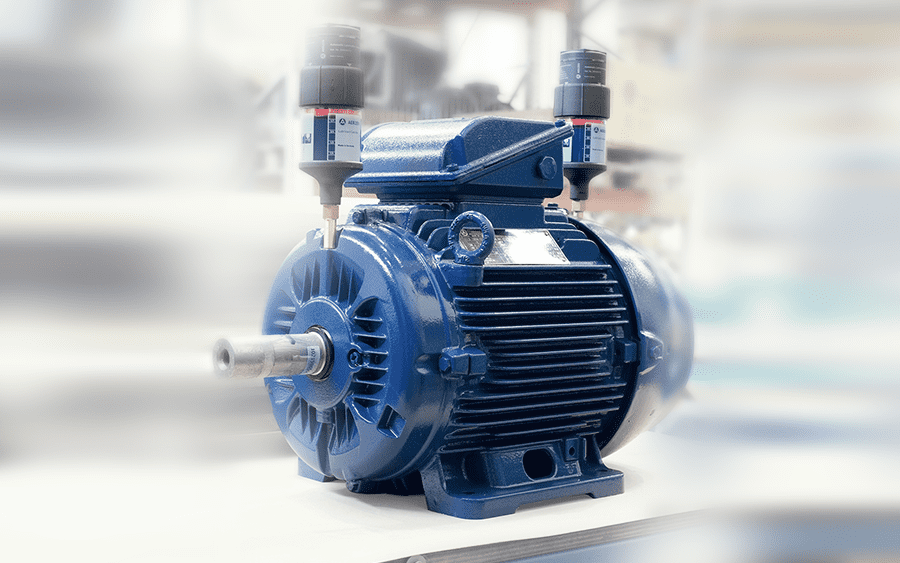

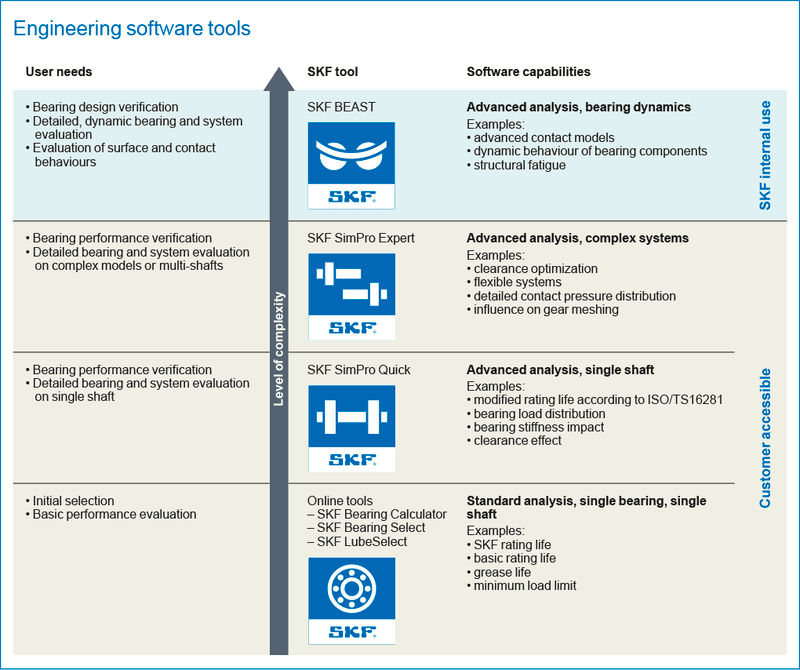

Regularly greasing your electric motor bearing is an important part of electric motor maintenance. Viscosity oil viscosity should be appropriate for the load and speed of the application at operating tempera ture. 2 for ball bearings spherical roller bearings tapered roller bearings and carb bearings rotational speed up to 210 000 and for cylindrical roller bearings rotational speed up to 270 000. If motor manufacturer instructions are not available determine the appropriate grease relubrication intervals for motors under normal operating conditions using figure 1 which is based on information provided by nsk bearing corp.

And since 40 to 70 of motor failures are related to bearings it s no surprise that high quality bearings are key for reliable motors. Run the motor for at least 20 minutes to purge any excess grease and then replace the drain plug. Able to handle light to moderate loads at high speeds this grease is often used on electric motor bearings for fans pumps and dryers. Grease relubrication intervals for normal operating conditions can be read as a function of bearing speed.

3 c p load ratio where c basic dynamic load rating kn and p equivalent dynamic bearing load kn.