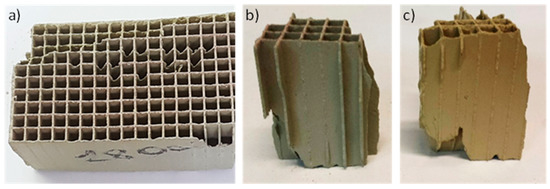

Drop Damage Ceramic Monolith

The above friction factors were compiled from the literature 175 174 laboratory evaluation of ceramic monoliths with square cells and metal monoliths with sinusoidal cells showed very good correlation with the respective coefficients in table 1 173.

Drop damage ceramic monolith. An empirical model has also been developed by ekstrom and andersson 14 to predict the pressure drop suitable for one dimensional 1d and 3d simulations. About 1 3 of the way down the main body of the kamado there s an intriguing little knob. They are distinguished among other diesel filter designs by high surface area per unit volume and by high filtration. Pulling on the knob reveals a small pullout chute.

Technically all kamados can smoke meat. Academia edu is a platform for academics to share research papers. Flow distribution within the monolith was found to depend strongly on diffuser performance which is modified strongly by brick resistance. Shop for apparel fun home and office decor electronics gadgets and collectibles find the perfect gift and more.

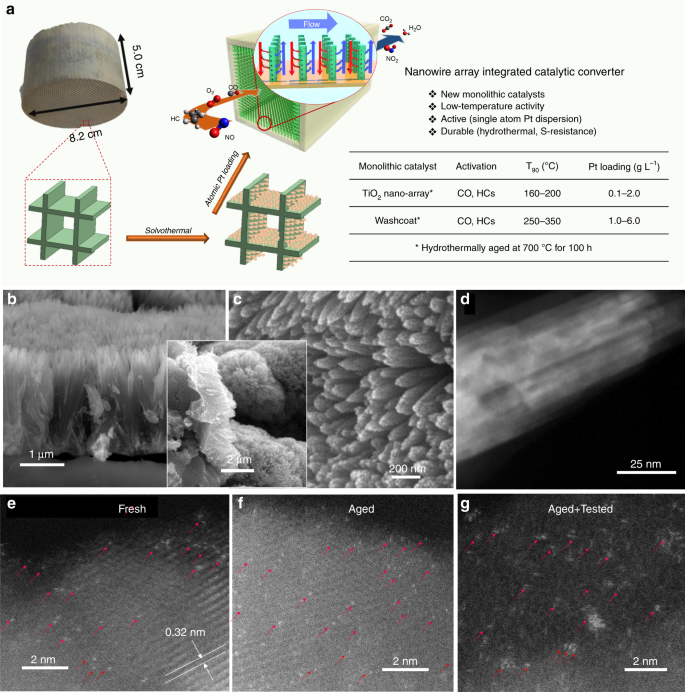

Pressure drop due to the headers and brick resistance and their relative roles is also identified. The monolith is insulated using an insulation mat wrapped around the monolith with a thickness of 3 mm. Since the substrate inlet and outlet pressure losses are relatively insignificant in the total catalyst pressure drop there has been little. What separates the monolith from the pack is its versatility as a smoker.

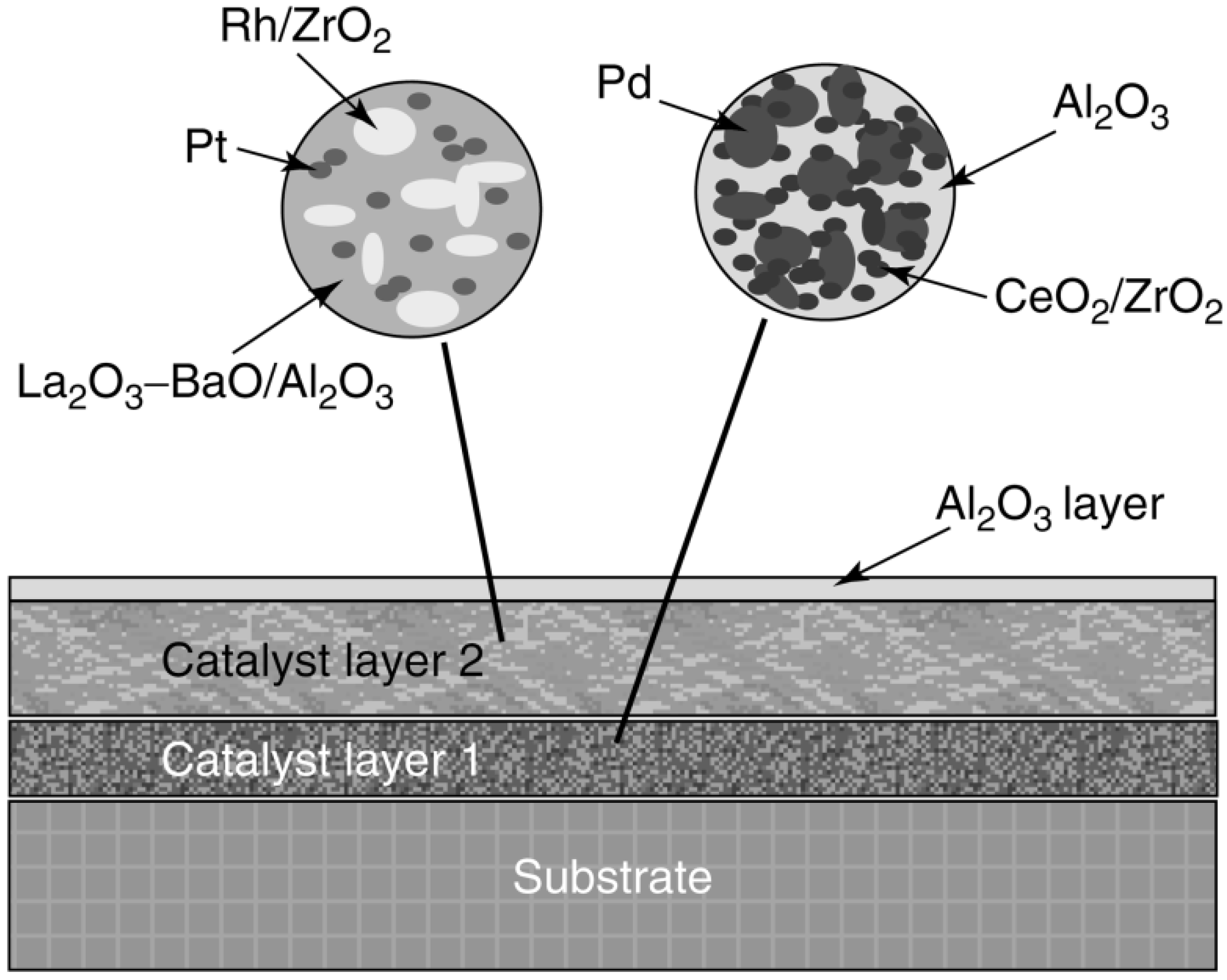

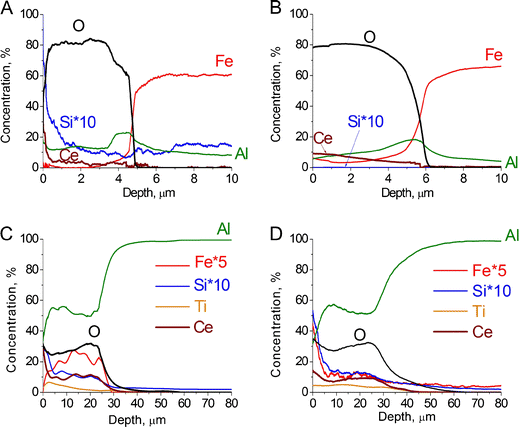

0 5000 10000 15000 20000 25000 0 10 20 30 40 50 velocity m s pressure drop length pa m porous monolith porous channelled monolith cylindrical beads honeycomb 400 12 honeycomb 500 12 figure 6. Ceramic wall flow monoliths which are derived from the flow through cellular supports used for catalytic converters became the most common type of diesel filter substrate. One or two layers of catalyst may be applied and higher no x reduction can be achieved with the use of higher amounts of catalyst two layers european commission and joint research center 2013. The catalytic converter assembly consists of a monolith with a cell density of 400 cells per square inch cpsi and a wall thickness of 6 5 mil 6 5x10 3 inch.

Ceramic honeycomb and pleated metal plate monolith designs are general configurations of catalysts u s. The monolith and insulation are inserted in a stainless steel cylindrical. Nevertheless the flow profile of a monolith is different from the accepted lamina r profile which is possibly caused by the high surface roughness of the channel 11. Buy thinkgeek products at gamestop.